Cable

- Mobile: 008613331906936

- Whatsapp: +8618358312481

- E-mail: admin@stronghoist.com

1. Working temperature for long time of wire core is not more than 65°C

2. Has the property of durability and suitable for outdoor touching of greasy dirt

3. Has the property of fire-resistance

Why do elevators use professional lift cables? Because the ordinary rubber rubber cable in the lift as a lift cable after a few months will be distorted deformation, drums, broken, broken core. Construction lifts frequently used in the role of torsional force under the cable at the bottom of fatigue and gradually deformed, so the general ordinary rubber cable is difficult to use in the construction of long lifts. In response to this situation we have developed a professional lift cable, using high-strength rubber, and special production process. I developed the elevator professional cable to meet the major domestic and international large lift equipment. With the increasing height of the lift, the requirements of the matching cable are very different, because the elevator running process, the cable will gather a lot of stress inside, when the lift height is greater than 120m [the traditional lift is about 70m] The torsional stress in the cable will be greater, the traditional cable for such lifts. In order to meet the equipment operation requirements, to extend the service life of the cable, to improve the original structure of the cable, to meet the construction industry needs of the lift industry.

Technical specifications for lifts dedicated cables:

1. Insulation resistance between cable insulation core conversion to the temperature of 20 ℃, should not be less than 50MΩ / KM.

2. The cable shall be capable of withstanding the static conductor.

3. Cable insulation between the core should be subject to exchange 500Hz2000V (300 / 500V class), 2500V (450 / 750V) voltage test 5min

4. Suitable for AC voltage 450 / 700V and below a variety of frequent movement of machinery, especially for construction lifts, construction elevators, lifting machinery. The long-term permissible temperature of the cable does not exceed 65 ° C.

5. The cable copper conductor with high purity oxygen-free copper. Sheath with high-strength rubber (non-ordinary ordinary rubber cable rubber) 20 ℃ when the conductor resistance per kilometer is not greater than 1.21Ω, the air laying allowable carrying capacity of 84A

The elevator cable with a special structural design, long life, the maximum increase in elevator production efficiency. Can provide overall electrical control in the case of longer suspension length, while taking mechanical stress. The elevator cable is made of steel wire and can be used for long distance suspension.

【Elevator cable】 product features

(1) multi-strand fine fine 99.9999% annealed ultra-fine oxygen-free bare copper wire to ensure the cable conductivity and cable flexibility;

(2) core insulation color coding distinction (core color optional);

(3) special structural design to optimize the cable pitch + fine copper stranded + special ladder cable material to ensure that the use of continuous bending back and forth movement;

(4) bare copper / tinned copper shield effectively resist the outside of the strong electronic interference (shielding optional);

(5) high-strength galvanized double wire bearing to ensure the service life of the cable (wire bearing optional);

(6) New special ladder cable special jacket - wear, oil, back and forth bending movement in high / low temperature still maintain the soft line.

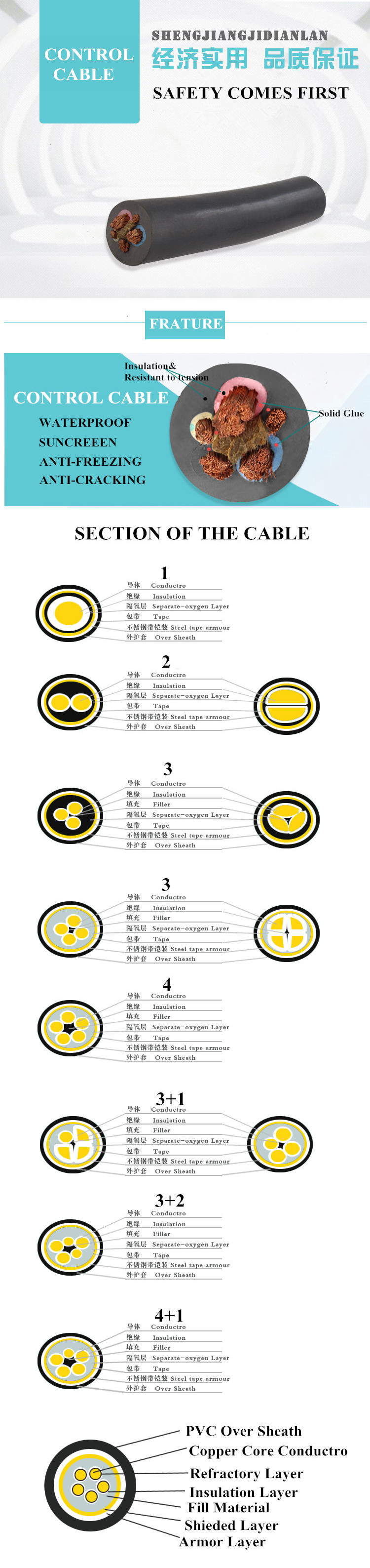

【Elevator cable】 cable structure

Conductor: multi-strand fine ultra-fine oxygen-free copper wire (99.9999% annealed oxygen-free bare copper wire)

Insulation: special mixed PVC insulation

Color: Color representation (yellow, white, orange, light green, pink) Numeric number

Lining: optional

Shield: copper mesh weave (bare copper / tinned copper) optional

Reinforcement: High strength galvanized steel wire (optional)

Sheath: special flexible lapel special sheathing material, gray or black.

【Elevator cable】 technical indicators

Rated voltage: U0 / U ≤ 1.5mm2 300/500 V

> 1.5mm2 450/750 V

Test voltage: U 2500V

Temperature range: -30 ℃ ~ +70 ℃

The minimum bending radius is required for the continuous operation of the elevator cable 6 * D

[Elevator cable] after-sales service

The company is committed to providing users with excellent products and solutions, with many years of experience in elevator manufacturing, we always be able to ensure that the product of good quality, based on products in different occasions under the special needs, we can solve the professional technology to meet the user The demand for the product.

The company has a number of strong technical force, experienced and innovative technical engineers, and has independent research and development capacity of the elevator cable for our customers to provide comprehensive pre-sale support services. Relying on the quality of stable supply channels, as well as strict and scientific internal management system to ensure that product quality has always been as rigorous as one. Not only to provide customers with cost-effective products, but also because of the use of different environmental and electrical characteristics of the wire and cable have special requirements to provide customers with the ideal solution.

Elevator cable

Elevator dedicated cable

Elevator line

Double wire flat elevator with accompanying network cable

Double wire with power supply flat elevator with the network line

Elevator Mobile Shielded Super Category 5 Wire Mesh Wire Wire Category 5 Wire Mesh With Power Cord Wire Wire Super Category 5 Cable

Elevator mobile shield 6 types of cable with wire 6 cable with power cord with wire 6 cable and so on

Product number:

1, mixed PVC ladder cable material

TVVB2G-UTP

TVVB2G-STP

TVVB2G-UTP + 2 * 1.0 TVVB2G-UTP + 2 * 1.0 TVVB2G-UTP + 2 * 1.0 TVVB2G-UTP + 2 *

TVVB2G-STP + 2 * 1.0 TVVB2G-STP + 2 * 1.0 TVVB2G-STP + 2 * 1.0 TVVB2G-STP + 2 *

2, resistant to cold special soft material

DT2G-UTP

DT2G-STP

DT2G-UTP + 2 * 0.5 DT2G-UTP + 2 * 1.0 DT2G-UTP + 2 * 1.0 DT2G-UTP + 2 *

DT2G-STP + 2 * 1.0 DT2G-STP + 2 * 1.0 DT2G-STP + 2 * 1.0 DT2G-STP + 2 *

Applications:

Cable with a special structural design, long life, to maximize the elevator production enterprises, elevator engineering installation companies, property companies and other elevator manufacturers, maintenance side and the use of the cable on the service life, performance, security and security requirements.

Elevator cable can be linked with the elevator control cable suspension, the use of wire bearing the cable can also be used independently (while taking mechanical stress). Can be used for long-distance signal transmission, a better shield anti-jamming effect, suitable for elevators and other mobile installation occasions.

Conductor material: multi-strand ultra-fine fine twisted oxygen-free copper wire, in line with VDE029CLASS 6 standard

Conductor structure: 7 / 0.19 7 / 0.2 19 / 0.16

Insulation material: HDPE, Dingqing rubber, polyurethane and so on

Core color brown * white / brown orange * white / orange green * white / green blue * white / blue

Power line; RVV2 * 0.5 RVV2 * 0.75 RVV2 * 1 RVV2 * 1.5 RVV2 * 2.5 optional

Sheath material for the elevator mixed with PVC material or Dingqing rubber (resistant to cold application environment)

Jacket Color Black (RAL9005) Gray (RAL7001) Orange (RAL2003)

Use temperature range;

Fixed installation; -30 ℃ to + 90 ℃

Mobile installation; -5 ℃ to +90 ℃ (special custom products up to -55 ℃ to 150 ℃)

Minimum bending radius; fixed installation; 5 * cable diameter

Mobile installation; when the trip <10 meters, the bending radius of 8 * d, when the stroke ≥ 10 meters, the bending radius of 10 * d

Elevator network cable, elevator dedicated network cable, elevator resistant bending cable, elevator wear-resistant cable