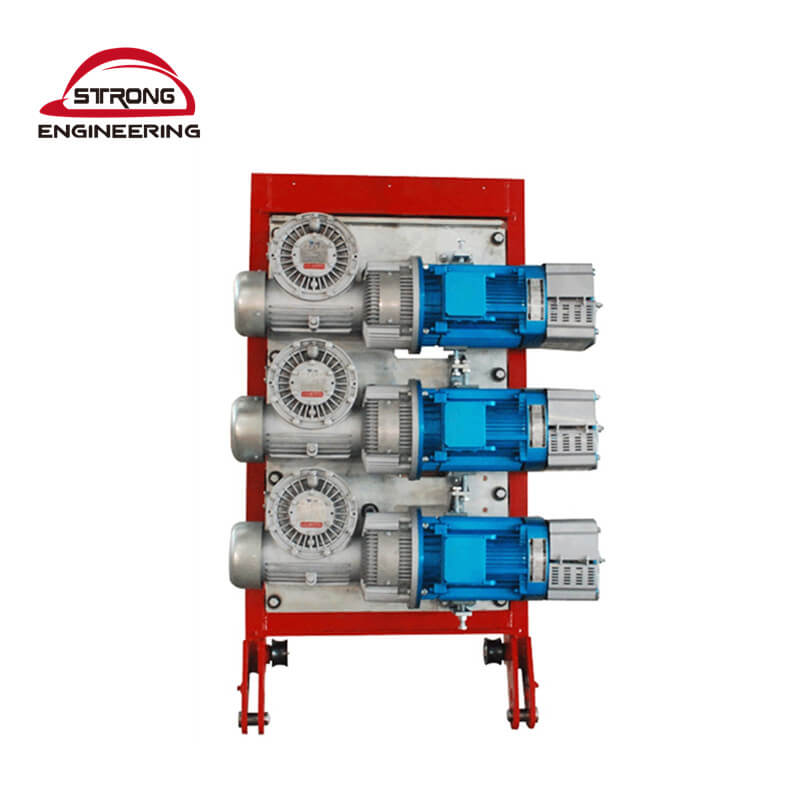

Reducer&part

- Mobile: 008613331906936

- Whatsapp: +8618358312481

- E-mail: admin@stronghoist.com

| Weight(KG) | Gear ratio | Center distance(MM) | Input power(KW) |

| 50 | 1/14 | 125 | 10.3 |

| 1/16 | 11.6 | ||

| 1/18 | 11.7 | ||

| Specification | |||

|

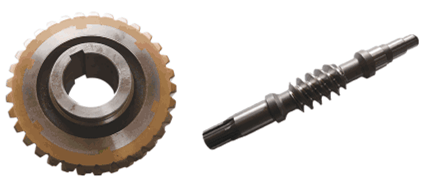

1. We adopt advanced circle-arc tooth in worm and gear, which means load capacity is excellent and transmission efficiency is high. 2. We also adopt high-quality seal and take air test before delivery to ensure great sealing performance. 3. In the meantime, every reducer will be made a experiment of running in to make sure that they run smoothly with low noise. 4. The worm’s machining accuracy is high and has passed quality test by German Klingelnberg detector. |

|||

| Regular size | |||||||

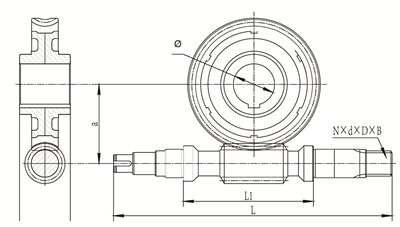

| Brand | Worm length | Bearings distance | Gear ratio | Center distance | Worm teeth | Keyway | Worm bore |

| Code | L(MM) | L1(MM) | i | a(MM) | (PCS) | (MM) | Ø |

| HUASHENGCHANG | 464 | 204 | 1/16 | 125 | 48 | 18 | 65 |

| HUASHENGCHANG | 411 | 173 | 1/16 | 125 | 32 | 18 | 65 |

| AOYA | 447 | 190 | 1/16 | 125 | 32 | 18 | 65 |

| AOYA | 450 | 190 | 1/18 | 125 | 36 | 18 | 65 |

| CAOSHI | 453 | 186.5 | 1/16 | 125 | 48 | 18 | 65 |

| TIANMING | 438 | 190 | 1/16 | 125 | 48 | 20 | 65 |

| TIANMING | 430 | 210 | 1/16 | 125 | 48 | 20 | 65 |

| XIANGHE | 427 | 177 | 1/16 | 125 | 48 | 18 | 65 |

| WANNENGDA | 395 | 152 | 1/18 | 125 | 36 | 18 | 65 |

| BAODA | 448 | 180 | 1/16 | 125 | 48 | 18 | 65 |

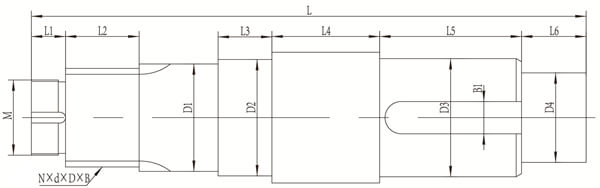

| Dimension drawing | Specification | ||||||

|

1. High processing precision 2. Have passed detection of quality detector, the working life is long 3. Bearing capacity is strong and transmission efficiency is high |

||||||

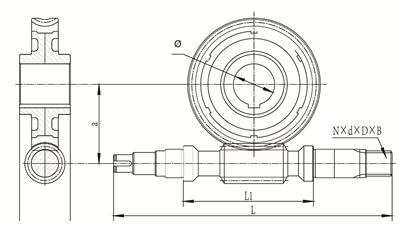

| Regular size | ||||||

| Brand | Code | JINGGANG | JIANGLU | BAODA55 | AOYA | XIANGHE |

| Weight | (KG) | 7.0 | 6.8 | 7.0 | 7.0 | 7.0 |

| Overall length | L(MM) | 298 | 294 | 298 | 312.5 | 292 |

| Step of thread | L1(MM) | 18 | / | / | 16 | / |

| Step of spline | L2(MM) | 40 | 53.5 | 45.5 | 41 | 54.5 |

| Step of big bearing | L3(MM) | 34 | 33 | 34 | 34 | 34 |

| Step of major diameter | L4(MM) | 55 | 44 | 44 | 58.8 | 45 |

| Step of worm | L5(MM) | 79 | 79 | 79 | 78 | 78 |

| Step of minor diameter | L6(MM) | 35 | 37 | 35 | 41 | 34 |

| Oil seal step diameter | D1(MM) | Ø60 | Ø60 | Ø60 | Ø60 | Ø60 |

| Large bearing step diameter | D2(MM) | Ø65 | Ø65 | Ø65 | Ø65 | Ø65 |

| Worm step diameter | D3(MM) | Ø65 | Ø65 | Ø65 | Ø65 | Ø65 |

| Small bearing step diameter | D4(MM) | Ø50 | Ø50 | Ø50 | Ø50 | Ø50 |

| Thread diameter | M | M42*1.5 | / | / | M42*1.5 | / |

| Spline | N*d*D*B | 6*49.5*55*14 | 6*49.5*55*14 | 10*45*56*7 | 6*49.5*55*14 | 6*49.5*55*14 |

| Keyway | B1 | 18 | 18 | 18 | 18 | 18 |

| Dimension drawing | ||||||

Circular cylindrical worm reducer: circular cylindrical worm reducer is the country to promote the use of high-tech products, can be widely used in lifting, chemical, mining, metallurgy, construction and other transmission equipment in the slowdown transmission, and other machinery industry , Is the industry in which the general reducer upgrade products (must use N320 turbine oil or 33 # oil).

It has a strong resistance to glue, vibration, smooth work, low noise, high transmission efficiency, low oil temperature and other major advantages.

Features:

1, lifting mast with high-strength aluminum alloy profiles, the whole light weight, easy to move.

2, the device power can be used according to user requirements 380V or 220V AC, can also be used batteries.

3, compact shape design, so that the machine can pass through a narrow channel or low hall.

4, up and down two operating systems, one can achieve lifting function.

5, a good man-machine interface, operating lights, leakage protection devices, high breaking circuit breaker readily available.

6, anti-pipeline rupture valve, emergency manual drop, cylinder piston limit, emergency stop button and other sets of safety protection measures to make the product more secure and reliable.

7, independent research and development of built-in high-strength wear-resistant fixed slider device to achieve the gap between the mast without the gap, so that the platform lift more smooth and comfortable. The double chain drive greatly increases the safety factor of the construction personnel at high altitude.

8, indexable leg stabilizer to the aerial work platform to minimize the operating blind spot

Product advantages:

1. Carrying capacity

2. Compact structure

3. Transmission efficiency is high

4. Smooth operation, low noise

5. Long service life

6. Reducing cabinet with high strength aluminum alloy material

7. High intensity and light weight