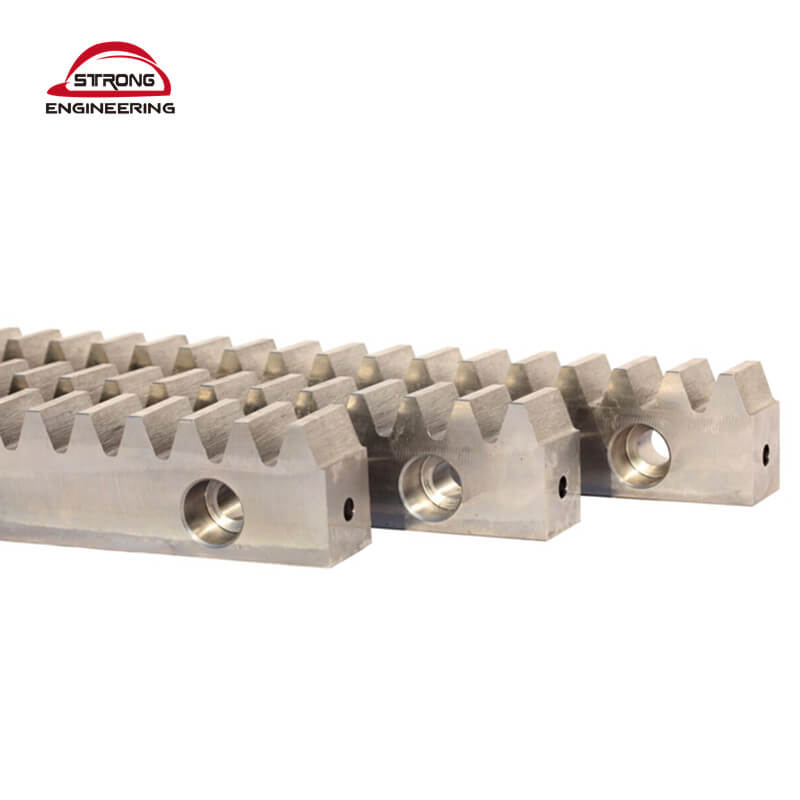

Mast Section(Tower Crane)

- Mobile: 008613331906936

- Whatsapp: +8618358312481

- E-mail: admin@stronghoist.com

Standard section features:

1. The main limb material with 135 * 135 square tube (Q345B manganese steel), high strength, strong rigidity, higher reliability;

2. Standard section can be used with different tower crane production company standard section, can effectively reduce the customer investment costs;

3. Steel from large companies, better quality;

4. The chord connection all use gas protection welding, the factory all through the weld inspection, the use of more secure, rest assured;

5. Standard section all through the whole shot blasting process, the surface is more smooth, beautiful;

6. The use of anti-corrosion sandblasting, the use of tower machinery industry's highest quality paint, highly attached, durable longer.

Tower crane standard section

Tower crane standard section in the crane, tower, tower crane and other mechanical equipment play an important role, a good standard section can not only improve these heavy machine

Tower crane standard section not only can improve the flexibility of the machine, but also improve work efficiency, if necessary, can also play a multiplier effect. 3 optional tower crane standard section

Then choose the standard section should choose what kind of it, many customers in the selection of the standard section of the time or can not carefully check the selection; now to introduce what kind of standard section is better.

The first look at whether there is no posted security labels, or regular manufacturers posted their own security signs, if not, the general so poor, unreliable quality, withstand the durability, so do not seek cheap, durable is Hard truth.

The second look at the standard section of the tower is made smooth and delicate, if so, this is generally more sophisticated, processing and other aspects of production are more in place, so that the standard deviation of the tower can not be bad.

Third look at the degree of convergence is good, whether the flexibility of the convergence, whether lubrication, if the rust, or the convergence of relatively slow, so the best not to buy, the general room of this time more often, usually not How to maintain, so pick the standard section to be careful. 4 tower crane standard section test Note:

The foundation of tower crane is an important link in the safety of tower crane. In accordance with the State Administration of Quality Supervision, "the supervision and inspection procedures for lifting machinery," routine tower crane inspection procedures are access to basic and track and other hidden project acceptance records. In the inspection, we must first pay attention to whether the base machine endurance is in line with the manufacturer's design requirements.

Tower crane standard section of the basic test should pay special attention to the following test points:

1. the problem of embedded parts

I believe that should be used to promote the use of embedded base or fixed legs, the use of embedded high-strength bolts, the material should be provided by the factory, manufacturers should provide test reports, and supervision by the construction unit reported to the competent units before being buried, and Do the relevant hidden acceptance records;

2. The tower foundation shall not be covered by soil

One is to increase the bearing capacity of the foundation, two is not conducive to observe the seat of the weld situation, tower crane project case has a base cover the tower crane, and the driver is more sophisticated, feeling tower crane abnormal sound, Immediately check the tower section of the standard section of the bolt again, did not find the problem, after the soil removed, the results found that the base of the steel structure of the weld cracks, the timely treatment, did not cause significant consequences.

3. Basic sinking form

The base sinking form refers to the bottom of the tower foundation below the standard of ± 0.00, placed in the basement of the basement of the bottom elevation of the form. For this kind of tower crane foundation treatment form, should pay attention to the foundation part of the tower drainage, to avoid water. According to the tower crane project case occurred with the tower based on the basic section of the water, affecting the driver, inspectors and failed to detect the base section of the base of the weld cracks, coupled with the weld at the serious damage to steel occurred ACCIDENT.

4. The base is placed on the slope

In addition to the above requirements, but also should take full account of the lateral pressure generated by the slope, the detection should be required when the construction unit in the excavation of the slope, should take anti-side pressure measures, such as to take soil nails Protection or the handling of bolt and other measures, in the detection of visits, the occurrence of too many causes of construction units did not consider the slope side of the pressure, earth excavation, caused by a serious deviation of the tower crane base case, to the construction unit Small economic loss;

At present, most of the tower crane foundation to the endurance requirements are generally 200 ~ 300kpa whether to meet the requirements. For the actual endurance did not meet the design requirements, check the tower crane standard section of the bolts whether the condensate injection and whether the bottom of the tower has been piling, the foundation to increase the corresponding treatment.