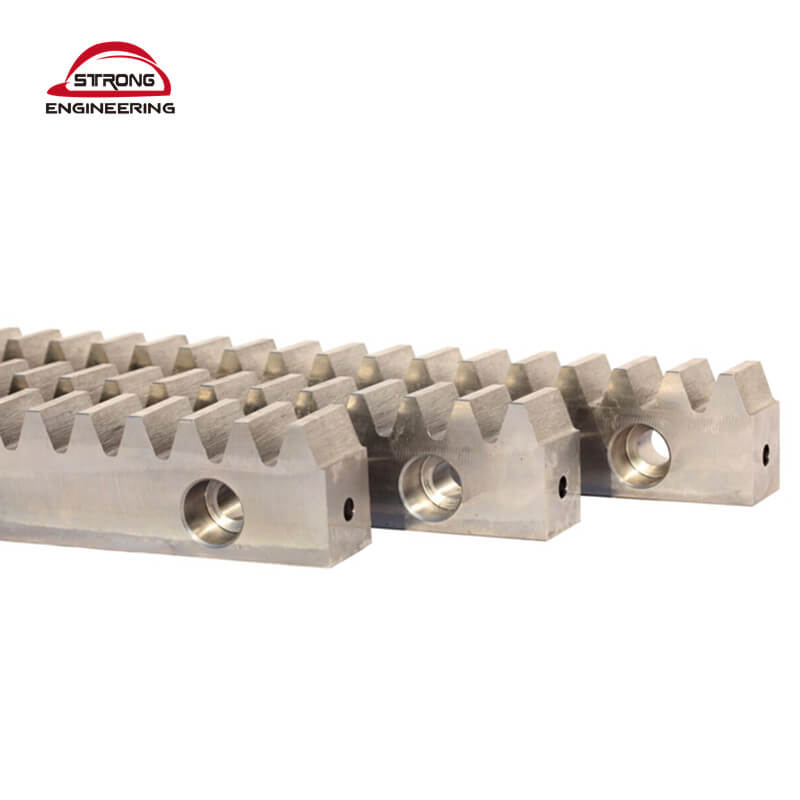

M8 Gear Rack

- Mobile: 008613331906936

- Whatsapp: +8618358312481

- E-mail: admin@stronghoist.com

| Module | Size(MM) | Surface treatment | Specification |

| 8 | 40*60*1508 |

Black coating/ Galvanized |

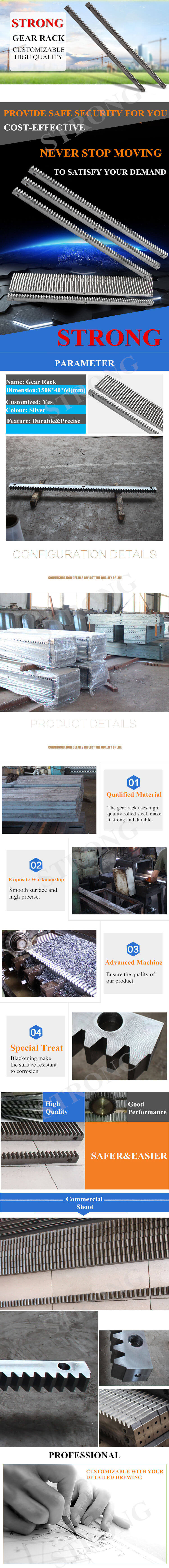

1. Made of stainless steel, precision casting, high smoothness 2. Difficult to rust 3. Non-standard custom is accepted with drawing |

1. Tooth type complete: a straight and helical teeth, to adapt to a variety of conditions of use; bar with a square and round, easy to use

2. Specifications complete: modulus 0.5 ~ modulus 12, the rack can be connected. Single processing length up to 2,000mm.

3. Material rich: carbon steel, alloy just and stainless steel. Japanese regulations for the S45C, SCM21, SCM440, SUS304; Germany for the C45E, 16CrMo44, 42CrMo4, X5CrNi1810.

4. Process multiple: heat treatment / no heat treatment, surface grinding / no surface grinding, tooth surface grinding / toothless grinding. The same modulus can have multiple intensities.

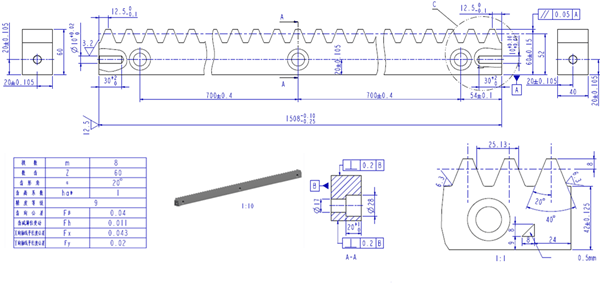

5. Accuracy of grinding grade Accumulated error 0.022mm / 300mm.

6. can be fully in accordance with customer demand for production.

Not only comparable to the precision of Germany and Japan, and the rapid delivery and price concessions

Product manufacturing process are using the excellent equipment and expertise in the strict supervision and quality control of the operation, the completion of a deep level of the product, the length of a two-meter-long processing for the domestic large and sophisticated CNC rack processing machine.

application

Suitable for fast, precise positioning agencies:

1. Suitable for heavy duty, high precision, high rigidity, high speed, long trip CNC machine tools, milling machines, drilling machines, lathes, machining centers, cutting machinery, woodworking machinery, welding machinery, stone machinery;

2. Suitable for factory automation rapid transfer mechanism, robot arm grasping agencies, intelligent three-dimensional warehouse.

3. Suitable for fast and accurate positioning mechanism

Features:

1. Accuracy of grinding grade Accumulated error 0.015mm / any 300mm;

2. With straight teeth / helical gear type, applicable to a variety of conditions of use; helical gear for the right angle of 19 ° 31'42 ", but also non-standard custom;

3. A heat treatment type / quenching and tempering treatment type, grinding grade / fine milling level, the same modulus, a variety of strength, a variety of precision;

5. With a square / round appearance, easy to integrate use; 5. Material diversity, established S45C carbon steel / SCM440 chrome molybdenum alloy steel, can also be flexible according to customer needs material selection (non-standard products and special specifications specifications )

This product can be used in the textile industry, industrial machinery, hardware, machine tools, automotive and other needs of the rack.

Professional precision rack manufacturers - marketing global used in machine tools, industrial machinery, automotive, automotive industry, the required rack for all kinds of CNC machine tools: cutting machines, lathes, milling machines, drilling machines, grinding machines, automated mechanical systems (Mechanical arm), automated storage systems.

Heat treatment: high frequency processing and quenching and tempering treatment Surface treatment: grinding, no grinding and dyeing black tooth surface treatment: finishing and grinding can be fully in accordance with customer demand for affordable production

First, the advantages

(1) Accuracy of grinding grade Accuracy 0.015mm / 300mm (any 300mm);

(2) with a straight tooth / helical tooth type, to adapt to a variety of conditions of use;

(3) with a heat treatment type / non-heat treatment type, the same modulus can have a variety of strength;

(4) with a square / round appearance, easy to integrate use;

(5) a variety of materials: alloy steel, stainless steel, engineering plastics (POM) and so on.

rack:

Zero backlash / high precision:

Innovative effective engagement, always ensure that more than two teeth in contact with each other in both sides of the teeth to ensure zero backlash, to ensure ± 20 micron positioning accuracy, each tooth tooth profile relative to the location of the first tooth are Accurate measurement is performed to ensure extremely high positioning accuracy and elimination of pitch error.

High-speed running capacity:

Roller rack drive system can achieve high-speed fax, the speed of up to 11 m / s, usually only by the linear motor can only provide high positioning accuracy, and in high-speed movement, ultra-low friction design does not produce heat or parts wear Travel length.

Linear roller rack drive system using modular design, Taiwan racks are 1 meter and 0.5 meters long two lengths, the German racks are 0.25,0.5,1,1.5,2,3 meters and other specifications can be based on application needs The combination can also be cut to a shorter length as needed, which is very useful for rack storage, efficient supply, cost reduction and interchangeability. The connection of the rack uses a special tool to accurately pass the position of the front rack through the rack teeth to the next rack.